Chemconserve

“Market introduction of products and technologies for the circular economy”

About Us

Chemconserve was originally established by the late Dim Kesber, and is an innovative company dedicated to the re-use of critical raw materials. The portfolio of completed projects since 1986 reflects how we have applied technology to re-use materials and contributed to the circular economy.

◇◇◇

Chemconserve successfully developed a market study for the EU funded REEcover project (2012-2016), focused on the re-use of the rare earths neodymium, dysprosium and praseodymium from electronic waste (WEEE) and mine tailings from the Kiruna mine. See the subsection on REEcover for more details and results.

◇◇◇

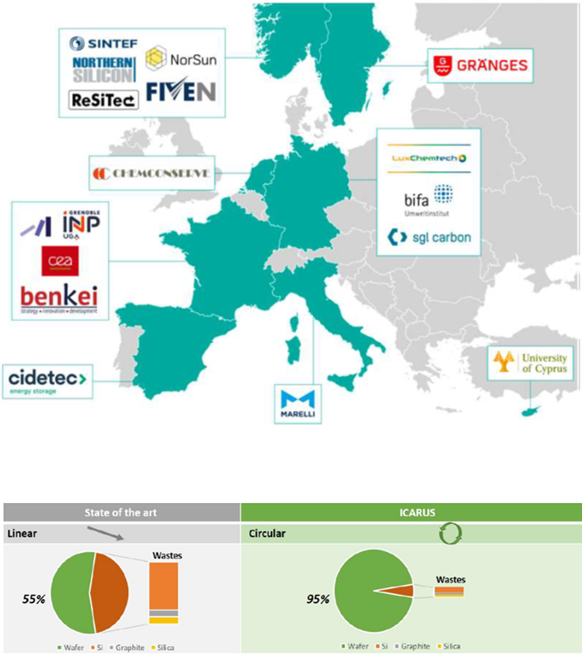

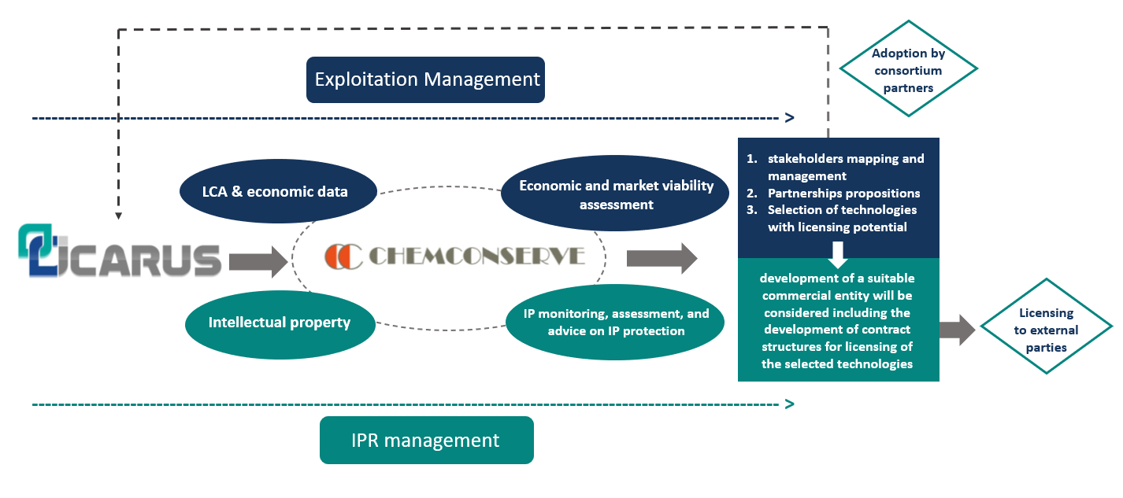

Currently, in the EU funded ICARUS project (2021-2024), Chemconserve is responsible for market studies, IPR management and the exploitation process of the technologies that are being developed to recycle the silicon kerf, graphite and silica that are generated in the production process of wafers. These losses (up to 54% of the raw material) are currently mostly landfilled. A consortium of 17 research and private organisations are developing innovative technologies to recycle these losses and Chemconserve assists in the development of markets for the resulting products and technologies.

◇◇◇

Our current trade business activities consist of the trade in Triphenyl Phosphine oxide (TPPO). The trade of TPPO has been one of the company activities for more than 20 years, with large multinational companies as our main clients.

◇◇◇

Our TPPO product has been re-used in various applications in chemical production as a result of the exceptionally high levels of purity, and the absence of TPP or other organics.

Current Projects

Past Projects

The Team

Marco Pieterse

Co-founder of Chemconserve BV

Responsible for project and business development

(MSc Wageningen University) is an early stage technology venture development specialist, with background in venture capital (World bank, Gilde Investments), and with experience in broad range of clean technology ventures, including energy technologies, agribusiness and water technologies. Particular focus as a venture developer on the conversion of innovative technology into marketable products.

Experience includes business planning and fund raising (several early stage companies), exiting of investments (e.g. successfully sold ECN’s fuel cell technologies to HC Starck and FCE), and licensing deals (e.g. licensing rare earth recycling technology to a large industrial conglomerate). Currently involved as an entrepreneur in several early stage companies.

Kees R. Nederveen

Co-founder of Chemconserve BV

Responsible for technology development and chemical trade

(MSc Utrecht University) is organometallic chemist and business economist of Utrecht University by training. He achieved 40 years of industrial experience, of which six years at DuPont International Switzerland in product management and market development of spunlaced fabrics. His career brought him in Akzo Nobel business management of Specialty Chemicals, followed by selection of joint venture partners for new Plant Investments and strategies in Asia/Pacific with successes in China, India and Malaysia.

Kees completed his industrial career as SBU President of Diosynth Inc North America, in manufacture and marketing of Active Pharmaceutical Ingredients. Has been involved in Deka Holding BV since 1998 as an Associate and acquired most activities from Deka Holding as a co-founder of Chemconserve BV.

Joep Hecker

Intern at Chemconserve BV

Responsible for market analysis & chemical trade assistance

(BSc University College Utrecht) is a master student currently enrolled in Science and Business Management (SBM) at Utrecht University. With a mixed background that includes a degree in Liberal Arts & Sciences -majors in Molecular Cell Biology and Chemistry- experience with fundamental lab research & a background in business related courses, Joep has an interdisciplinary approach that is relevant for the activities of Chemconserve, including chemical trade & the conversion of innovative scientific technologies into marketable products.

TPPO

Triphenylphosiphine oxide

Synonyms: TPPO

CAS number: 791-28-6

EINECS number: 212-338-8

Formula: [C6H5]3 OP; [C18H15] OP

Molecular weight: 278.29

HTS number: 29310095 (TSCA)

Water hazard class 2: hazardous to water

UNIQUE QUALITIES:

• Very high purity of 99.98%

• EU-origin

• Compliant with REACH regulations

• Product of choicefor multinationals

• No detectable TPP or other organics

APPLICATIONS e.g.:

• Flame retardant

• Organic synthesis a.o. dehydrogenation

to unsaturated compounds

• Crystallizing agent

• Epoxy curing agent

• Anti-fouling agent in ethylene furnaces

• Metal extract and together with TOPO

• As polymer film in capacitors

Storage facilities and logistic handling of our TPPO is carried out by Tigro Industries NV of Lommel, Belgium, a highly experienced warehousing and logistics company for customers in the industrial market, such as chemicals and pharma. For chemical goods specifically, Tigro Industries offers extra services like repackaging (e.g. big bags), blending, drying, micronising, formulising and labelling (traceability). Tigro offers a qualitative, trustworthy, safe and efficient solutions concerning storage, distribution and the handling of our products.

• 35 kg net UN-approved fiberboard drums in sealed plastic bags

• 40 kg fiber drums (2* 20 kg bags inside)

• Other packaging requirements are available upon request.

Product Analysis

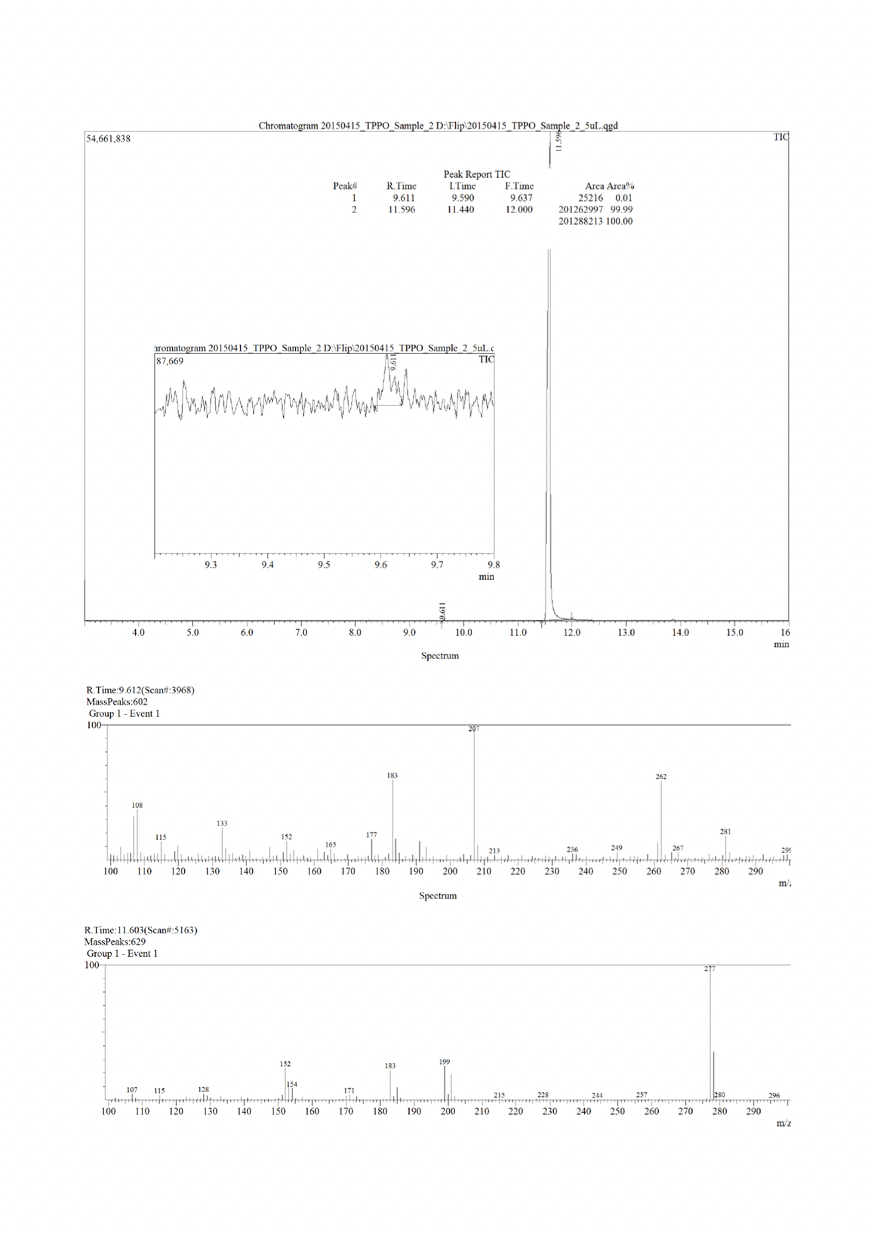

Analysis by the Faculty of Sciences of the Vrije Universiteit Amsterdam, Department of Chemistry and Pharmaceutical Sciences, Division of Organic Chemistry, Dr. Chris Slootweg: “Shown is a GC/MS analysis of the sample, indicating 99.98% purity on gas chromatographic basis (topmost graph). Specifically, no presence of Triphenylphosphine could be detected at its characteristic GC retention time of 9.69 minutes (middle graph, insert of topmost graph). The analytic methodology used allows us to detect triphenylphosphine quantities down to 0.08% (not shown). The mass spectroscopy results of the predominant chemical component in the sample confirm that the component comprising 99.98 % wt. is indeed TPPO (bottom graph).”

| Solubility | Partly soluble in water, soluble in aromatic hydrocarbons, ether, chloroform, acetone, slightly soluble in ethanol |

| Melting point | 155 °C |

| Flash point | 180 °C |

| Boiling point | 360 °C |

| Odor | weak, characteristic |

| Bulk density | 0.7 kg |

| Sort of Test: | Typicals: | Requirements: |

| Appearance | Cream colored powder | Cream coloured powder |

| Loss on drying (1 hour at 105 °C) | 0,16%w | Min 0,2%w |

| Melting point | 156,5 °C | Min 155 °C |

| Assay dry product | 99.8%w | Min 99,5%w |

| TPP | 0,08%w (under detection limit) | Max 0,2%w |

| Water (by KF) | 0,077%w | Max 0,1%w |

Contact

Marco Pieterse

![]() +31-653189899

+31-653189899

![]() m.pieterse@chemconserve.com

m.pieterse@chemconserve.com